Project Overview:

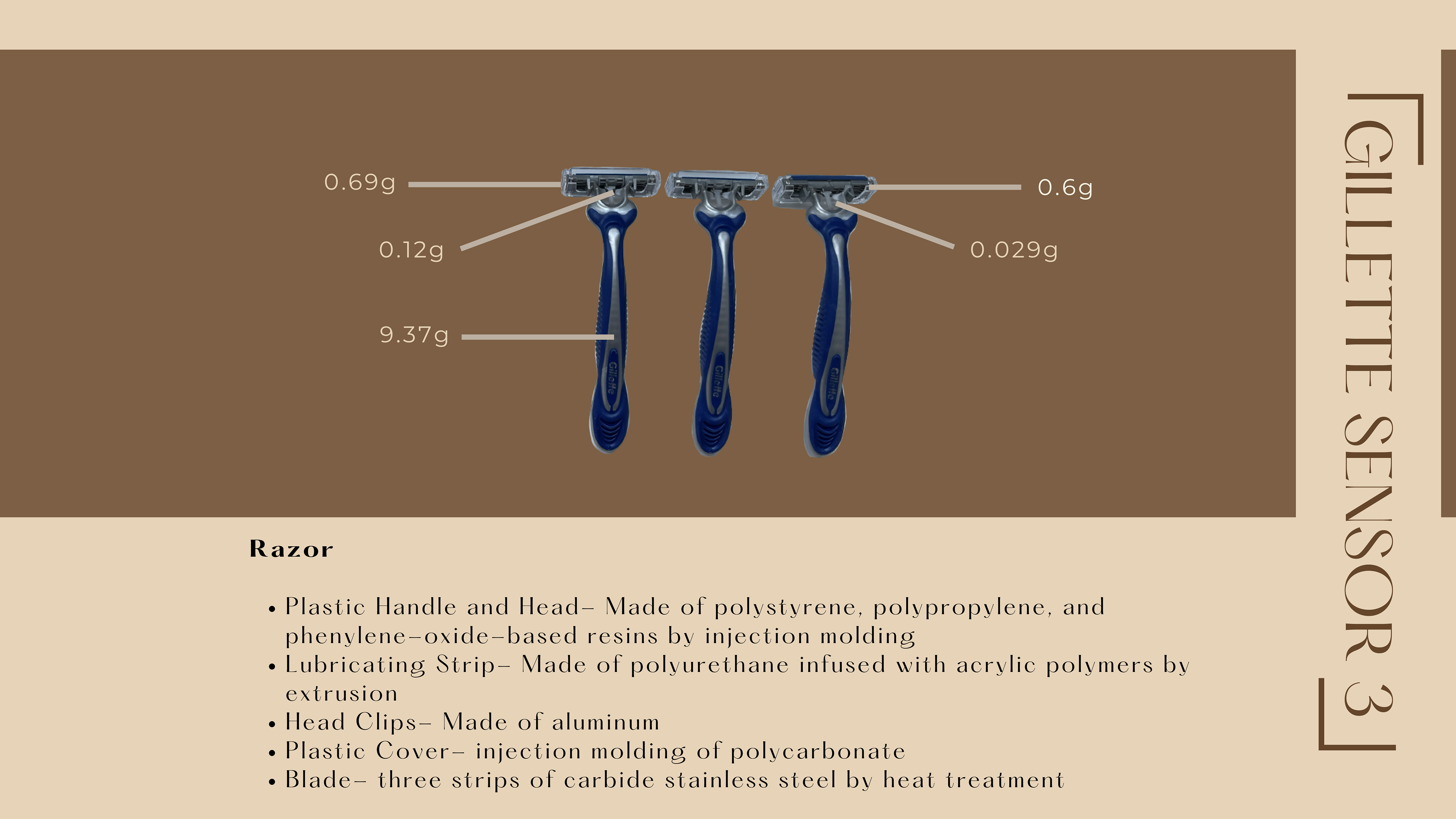

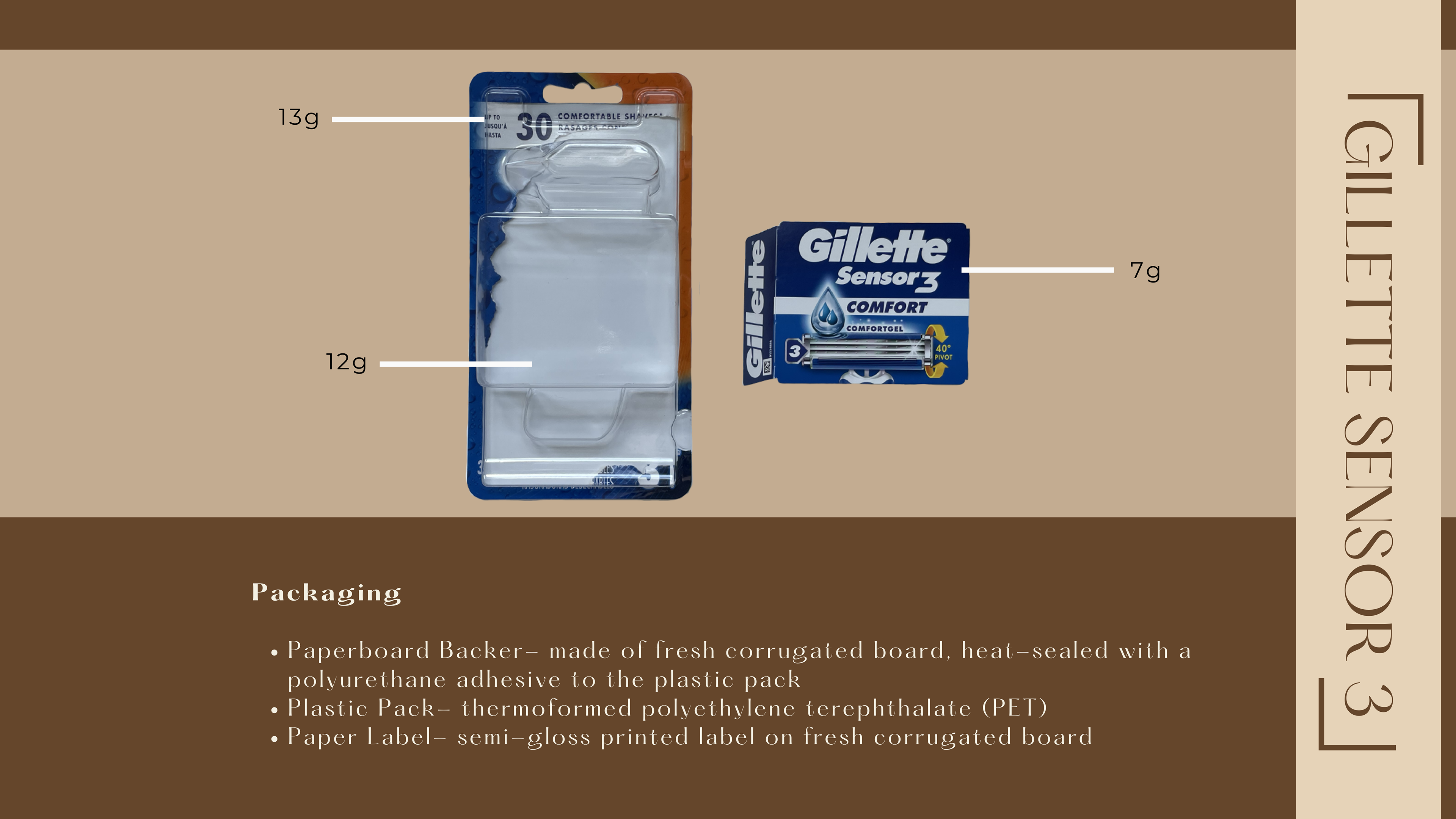

My team and I were tasked to conduct in-depth research on the life cycle of a product and identify opportunities to create the next-generation sustainable product or service solution for this product. For this project, we chose to dive deeper into razors, using Gillette as a case study.

My Role:

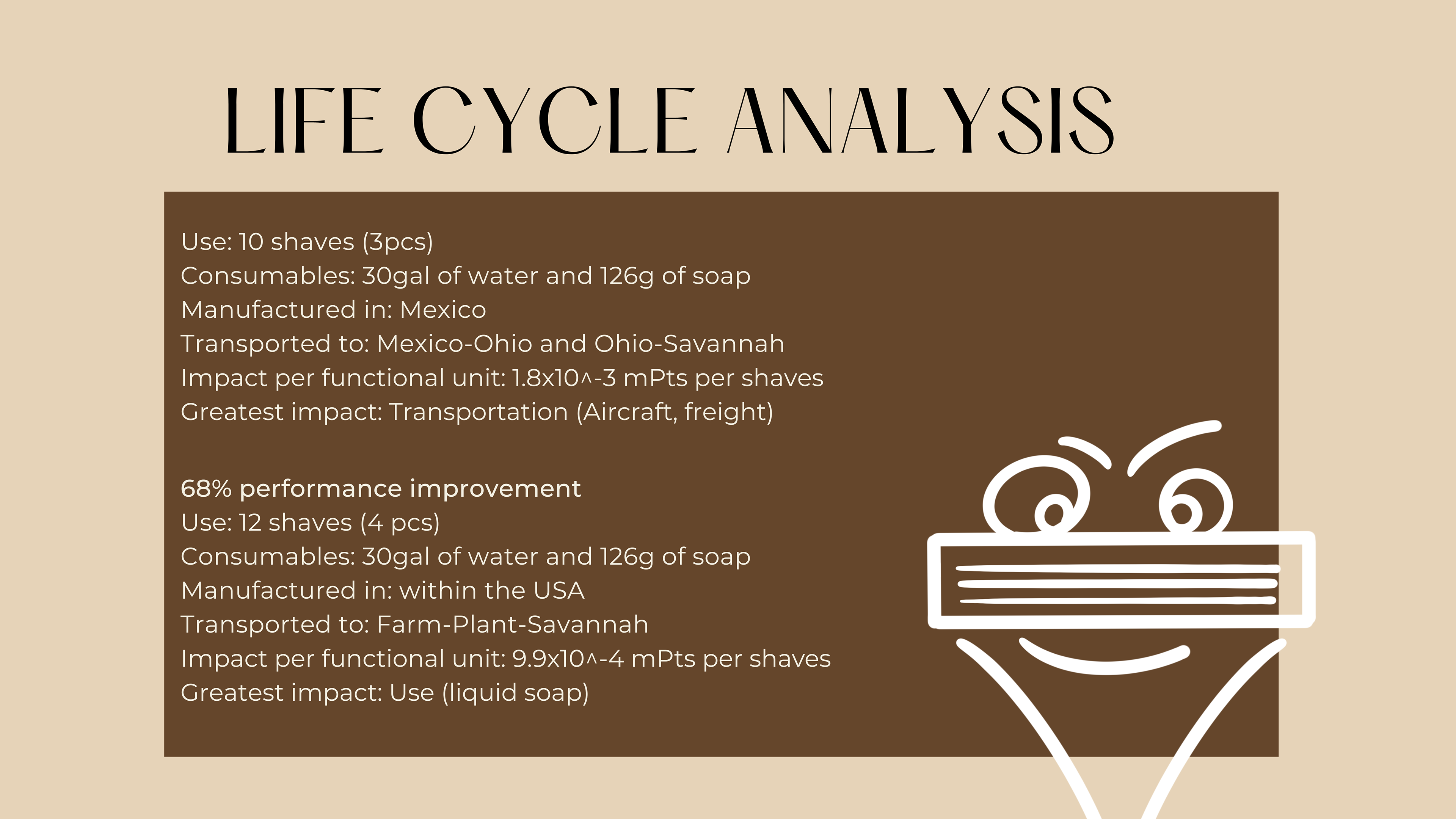

I undertook the responsibility of conducting a comprehensive life cycle analysis for the existing Gillette razor, examining its environmental impact from production to disposal. Using Sustainable Minds, I meticulously evaluated various sustainability indicators, including resource consumption, emissions, and waste generation. Subsequently, I compared the results with our new razor design to ascertain whether our innovative approach represents a substantial improvement in terms of sustainability. This rigorous analysis provided valuable insights and guided the decision-making process, ensuring that our design aligns with our commitment to minimizing environmental impact.

Design Process:

Preliminary Research

Final Design- Razor + Packaging

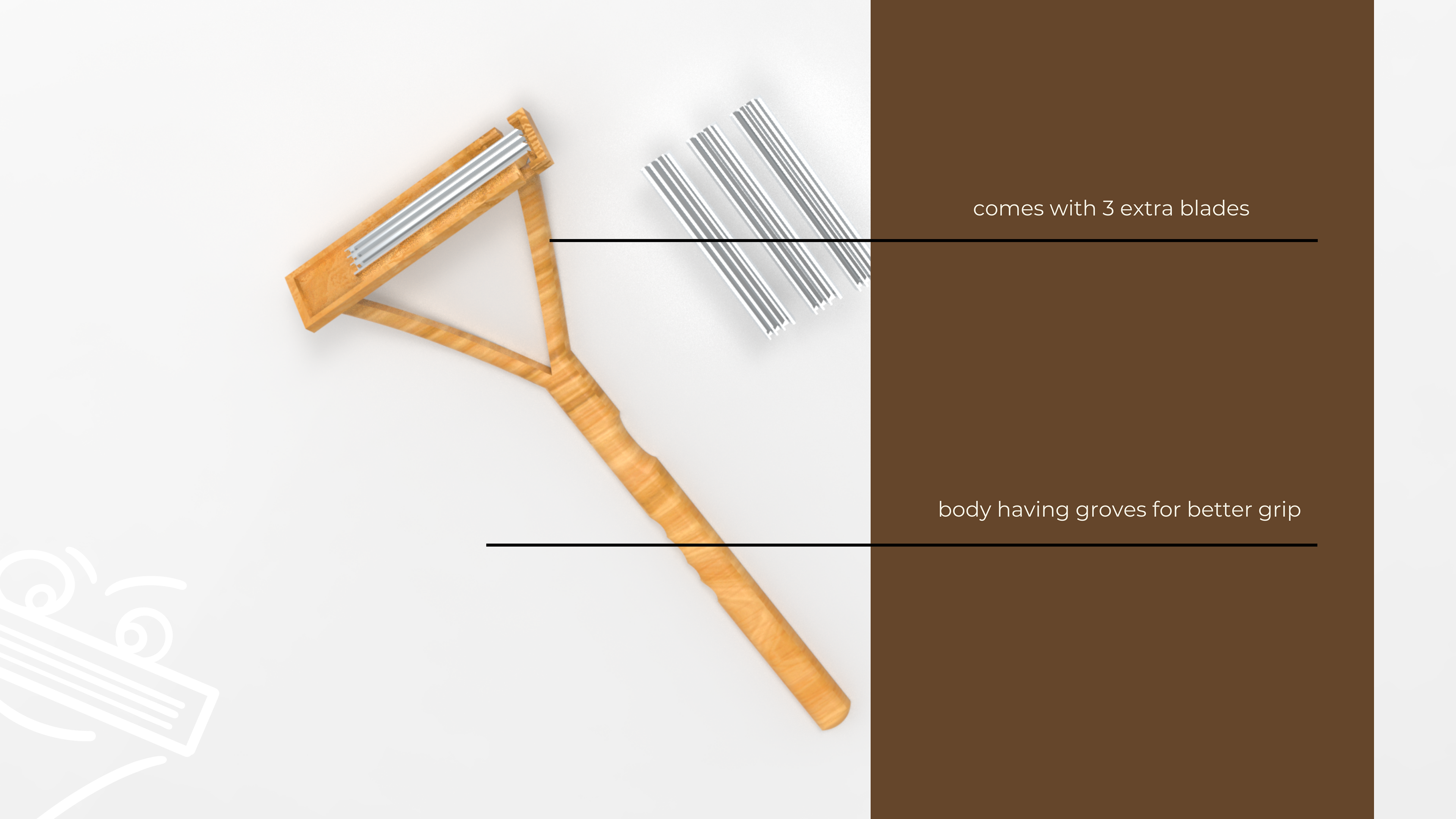

We are proud to introduce our new razor design, which incorporates sustainable practices from its manufacturing to its usage. To minimize transportation costs and reduce carbon emissions, the manufacturing of the razor will take place in the United States. The materials for the razor's handle, made of bamboo, will be sourced from Thigpen Bamboo Farm in Doerun, Georgia. From there, the bamboo will be transported to a manufacturing plant in Albany, Georgia, ensuring a localized and efficient production process.

For the razor blades, we have partnered with Personna, a razor blade manufacturer located in Verona, Virginia. By collaborating with a nearby supplier, we further minimize transportation distances, contributing to overall sustainability efforts.

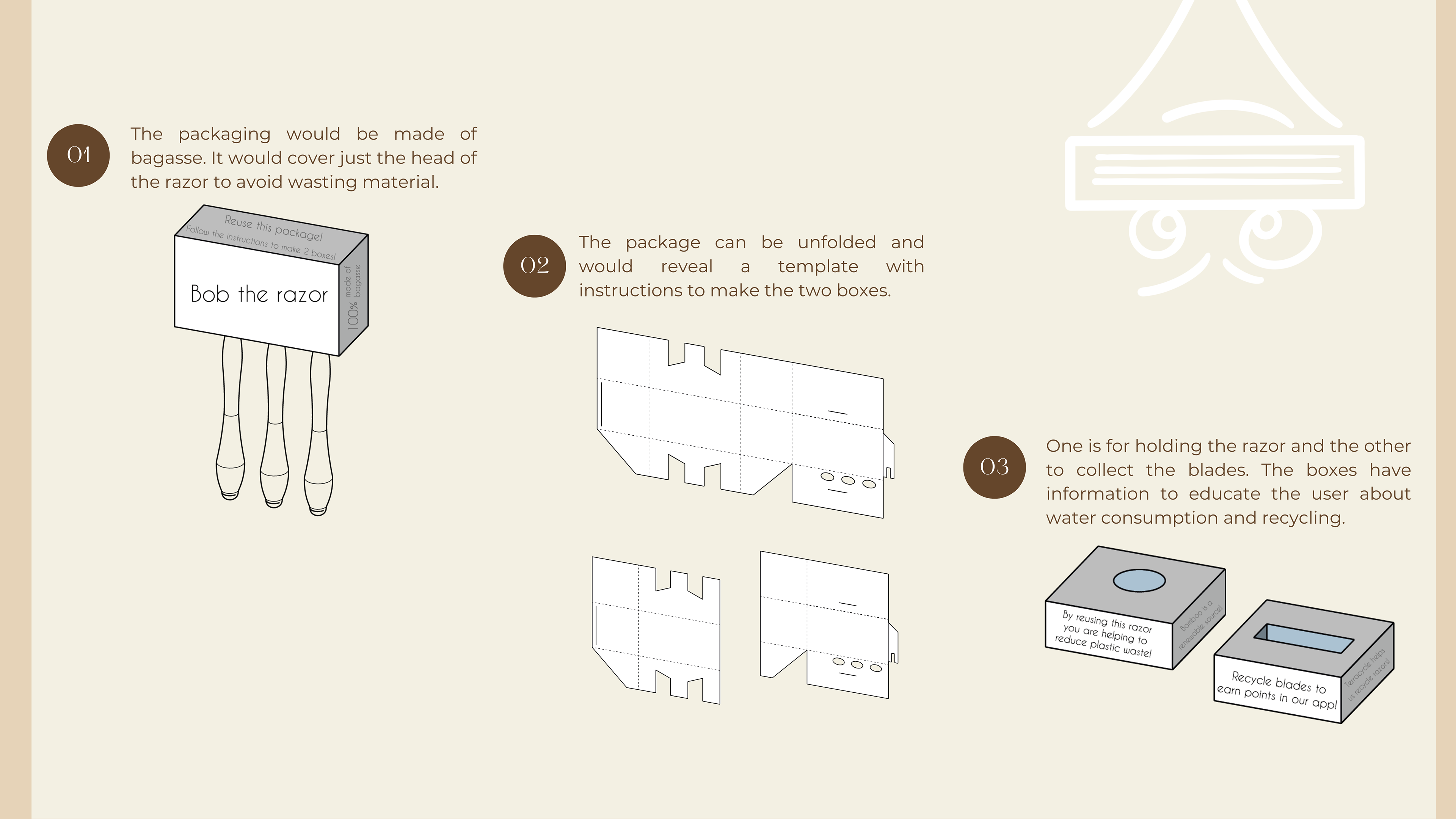

In line with our commitment to eco-conscious packaging, the materials for the packaging will be sourced from St. Joseph's Plantation, a sugarcane factory in Louisiana. The packaging material, made from bagasse, will be transported to the manufacturing plant to be utilized in production. Not only does this choice reduce waste, but it also contributes to the circular economy by utilizing by-products from sugarcane production.

To ensure the longevity of the razor head, we recommend shaving outside of the shower and using an 8oz glass of water to rinse the blades. This practice helps prevent moisture-induced dulling, allowing for a longer lifespan of the razor.

To enhance user convenience and sustainability, the packaging of the razor is designed to transform into a box where the razor can be safely stored when not in use. Additionally, the packaging includes mini compartment boxes for collecting shaved hair and used razor blades. When the compartments are full, users are encouraged to take the collected razor blades to Kroger for proper recycling.

Life Cycle Analysis:

Looking Forward:

Through these thoughtful design choices and responsible usage recommendations, our new razor design embodies our commitment to sustainability, local sourcing, and reducing waste. Together, we can make a positive impact on the environment while enjoying a high-quality shaving experience.

SCAD | Fall 2022 | Mentored by: Professor Satyakam Sharma | Sustainable Materials